The primary objective of nanomanufacturing is the establishment of sustainable, high-yield procedures for the commercial fabricating materials, constructions, gadgets, and subsystems at the quantum level. It has subsequently been a growing area of study and development for industry segments. Through this article, we will give a brief idea that would help get proper knowledge about nanotechnology.

The future of nanotechnology

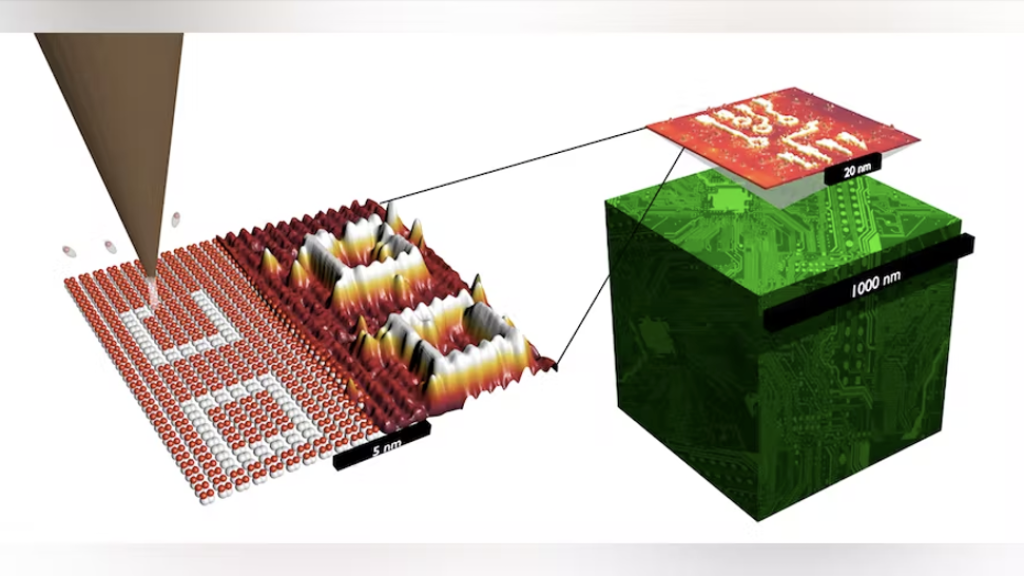

Nanotechnology may eventually make it possible for items to collect energy through their surroundings. With just a high catalytic activity, micro and nano ideas are now being researched to generate power using motion, radiation, weather patterns, hypoglycemia, and other substances. The process that is most frequently utilized to design circuit boards, as well as other commonplace products, is this one. The hierarchical procedure entails cutting nanomaterials from larger objects, which is one of two ways engineers might create nanomaterials. The latter is the lowest part approach, which entails simultaneously building a single structure component at the microscopic level. This procedure is time-consuming and difficult, and it is currently in the exploratory phase of its creation. You can learn more about Nanotechnology by following the link.

Applications of Nanotechnology

● Enhancing Safety

Nanostructured materials incorporation into varnishes has greatly advanced safety apparel and grown in popularity for textiles. Above mentioned safety garments can be used in production to shield employees from danger. A coating of nanofibers is produced when carbon particles as small as a nanometre are scattered within the fabric’s original threads. The fabric composite made with single-walled carbon nanotubes renders the clothing solvent, blemish, and antibacterial. Hence, nanotechnology is the future of manufacturing.

● The efficiency of Fuel

To create compounds for adhesion, varnishes, coverings, gardening, and encapsulating, polymeric nanotechnology entails dispersing nanostructures into the matrix of an already-existing polymer. These applications may acquire thermal conductivity, corrosion and oxidation stability, better mechanical properties, and even inferno resistance by nanoparticle reinforcements. Enterprise planning software will be crucial to the quality assurance and accountability of nanotech-based goods as the usage of nanoparticles in production increases.

● Friction Reduction

The field of nanoparticles in grease manufacture has opened the door to more creative fabrication options. Nanotubes can be utilized where lubricants are usually used to lessen friction between two objects. These nanoparticles reduce the possibility of heat, wear, and oil failure by spinning between the contact objects like small ball bearings. This discovery could be ground-breaking for the industry’s fate and ecology due to the finite availability of carbon fuels.

Conclusion

It has been said on tech weep blog that traceability will be essential for effectively, ethically, and effectively utilizing nanomaterials.Although nanotechnology has a promising future, it will take full transparency to realize that promise. Nanotechnology producers must create comprehensive standard operating procedures supported by completely integrated software systems to identify problems and immediately prevent home consumers from becoming impacted. The process is crucial for nanotechnology to be the future of manufacturing since it may directly impact customers in sectors like agriculture or aesthetics.